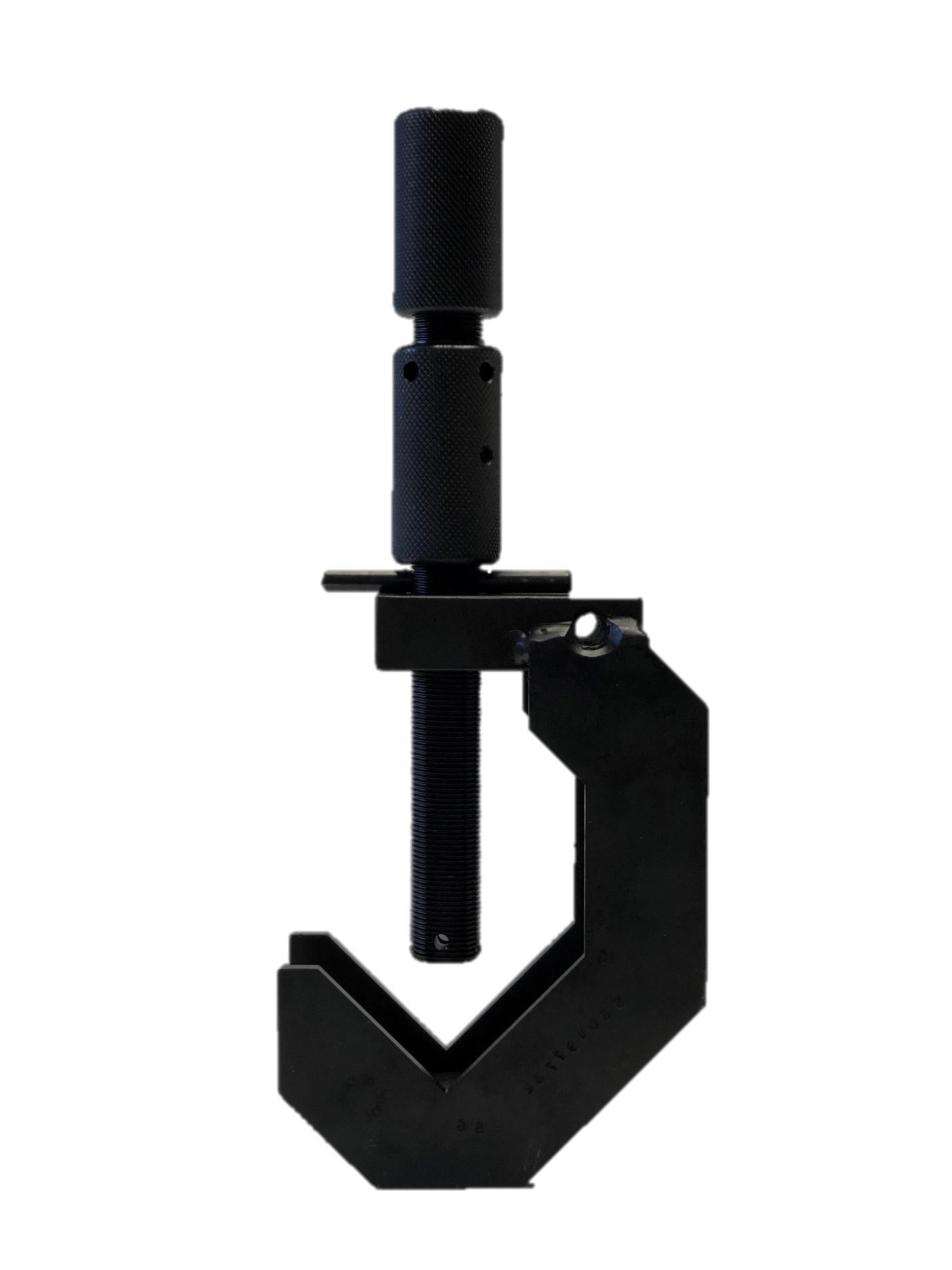

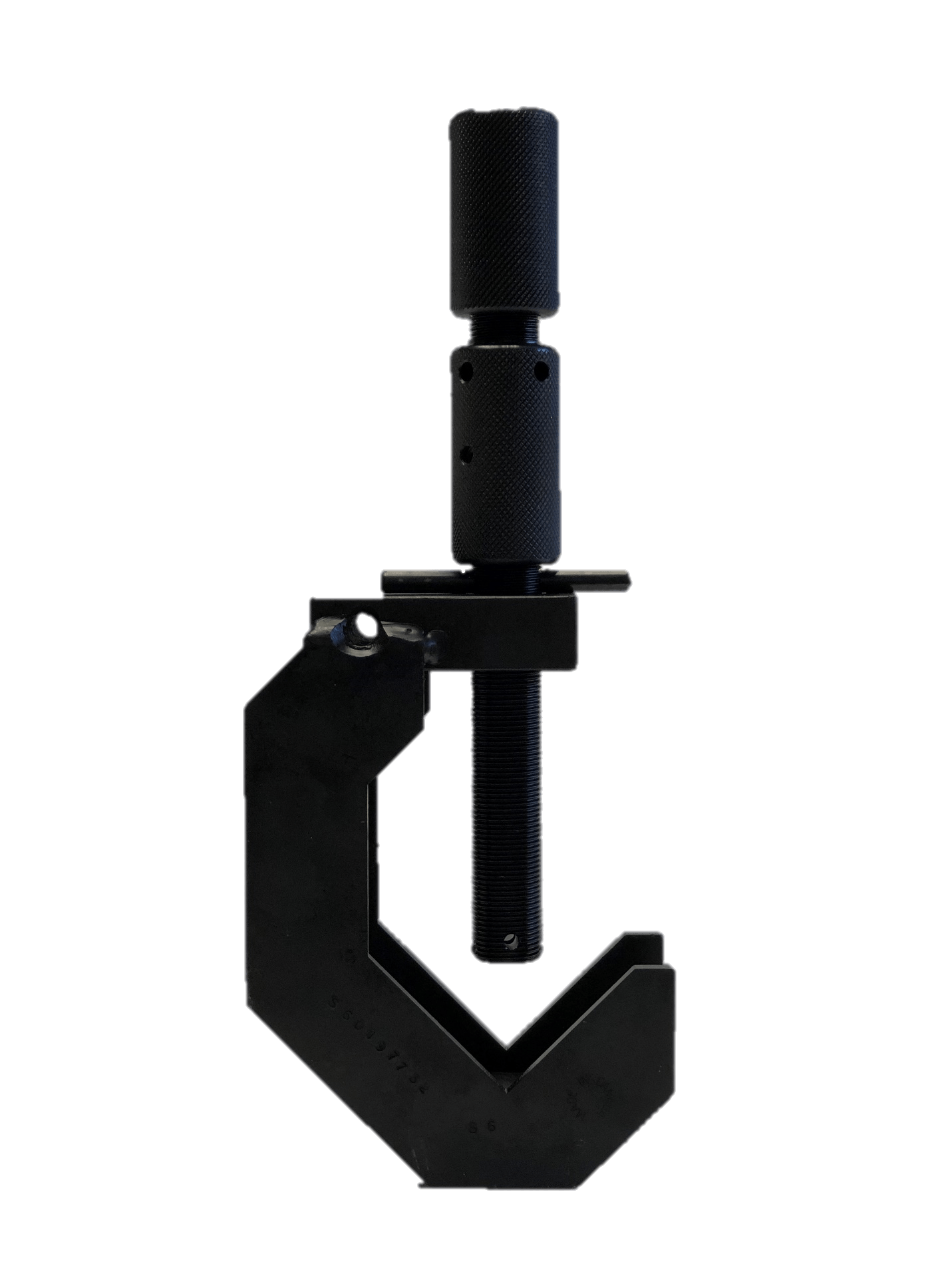

Spike Tool

For information regarding distributor opportunities, contact us today!

Responsible cable maintenance personnel must be able to positively ensure an underground electric power cable is de-energized prior to cutting, especially if the termination points are not visible.

- SPIKE provides positive assurance that an underground cable is not energized.

- SPIKE is designed to ensure the spike pierces the cable directly through it's center core.

- SPIKE is operated remotely thereby removing the cable maintenance personnel from danger, if a live cable is spiked.

- SPIKE can be used on thermoplastic or thermosetting insulation, as well as oil impregnated paper insulation.

- SPIKE can be used on aluminum and lead sheathed cable and interlock armored cables.

- SPIKE will accept single conductor cables ranging in diameter from 3/4" OD to 2-3/4" OD at all voltages. A larger tool can accommodate cable sizes up to 3-1/2" OD.

- SPIKE creates minimal damage to the cable.

- SPIKE is not cumbersome to use in the field. It weighs only 7 lbs.

- SPIKE is fast and easy to operate.

WHY "SPIKE" A CABLE?

Orders must be placed through Lakeport Power Ltd. (Global Distributor)

SPIKE TOOL BONDING

Spike Tool Lab Tests

Please click here to download the PDF document with the test results of the SPIKE Tool lab test.

The videos below show the SPIKE Tool piercing various common live single conductor cables under varying fault current conditions. They also have different grounding conditions which should be reviewed carefully. These videos were taken as part of the testing by Kinetrics. They show the performance of the SPIKE Tool under severe but possible field conditions. More importantly they show the energy released when a live conductor is pierced at high fault current levels. The tool performs well and the videos show clearly why remote operation, via a lanyard, is necessary for personnel safety.

Lab Test 1 — Test 3234

12 kA, 15 Cycles General Cable, 500 MCM, Copper, 15kV Ungrounded

Lab Test 1 — Test 3235

12 kA, 15 Cycles General Cable, 500 MCM, Copper, 15kV Grounded Spike Tool with U-Bolt

Lab Test 1 — Test 3236

12 kA, 15 Cycles Prysmian 750 MCM, Aluminum, 15 kV Grounded Spike Tool with 25mm Ball Stud

Lab Test 1 — Test 3237

27 kA, 15 Cycles Prysmian 750 MCM, Aluminum, 15 kV Grounded Spike Tool with 25mm Ball Stud

Lab Test 1 — Test 3238

20 kA, 15 Cycles General Cable, 1000 MCM, Aluminum, 28 kV Grounded Spike Tool with 25mmNew Paragraph

To ensure 100% safe operating efficiency, the manufacturer recommends maintenance of the Spike Tool every two years. The internal parts of the Spike Tool will wear with continued use over time or have reduced functionality due to operating in harsh field environments.

Contact Lakeport Power for a manufacturer inspection and overhaul. An estimate for repair and maintenance will be provided for your approval before commencing work. The Spike Tool will be restored to peak operating performance. There is a one-year manufacturer maintenance warranty, the same as a newly purchased tool.